SF Glaser, Inc

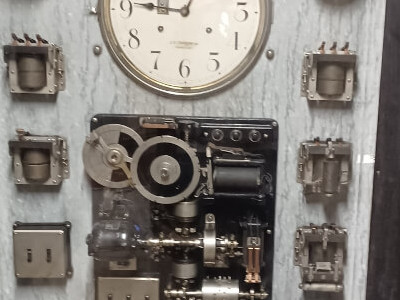

Cast Bronze Bell, Clock Tower, Electric Bell (Carillon System) Maintenance, Repair, Sales & Installation

Church Bell, University Bell & Tower Bell Repair & Maintenance Explained

Click Here for Electronic Bells & Carillon Systems

Churches Bells have been featured in worship since the 5th century when Italian monks revived the ancient art of bell founding, originally developed in China as early as 2000 BC. Today, church bells, university bells, & tower bells are cast in the same bronze alloy of copper and tin as then in the approximate ratio of 4:1. This is a considerably higher tin content than what is found in any other application and produces a metal with sufficient hardness to withstand repeated blows of the clapper, corrosion resistance and richness of tone.

Church bells, university bells, & tower bells come in numerous different sizes, with small handbells weighing less than a pound to several ton bourdon bells, the heaviest of the bells that belong to a musical instrument, a chime or a carillon, and delivers its lowest tone. Distinctive shapes of church bells, university bells, & tower bells have evolved in different parts of the world to satisfy the varying tastes for their harmonics. In the West, bell profiles have remained generally unchanged for numerous centuries. The one thing however that all church bells, university bells, & tower bell shave in common is their eventual need for restoration and or repair.

We can restore a church bell, university bell, & tower bell bell back to working order by making your bells swing properly again, welding a cracked or otherwise damaged bell, repairing it, or recasting a now broken bell. Additionally, wheels and frames can also be renewed back to their original new condition and missing or no longer available bell parts required to complete your project can be fabricated.

With respect to restoration of church bells, university bells, & tower bells, here are the most common areas requiring service:

Church Bells, University Bells, & Tower Bells Clapper Suspension

Clappers, usually of wrought iron, are suspended inside bells. Until the late 19th century this was achieved by inserting an iron ‘staple’ into the mould prior to pouring the molten bronze. On solidification, part of the staple was embedded in the crown and part exposed on the underside from which a clapper could be hung. Iron corrodes to iron oxide (rust) which occupies a greater volume than the parent metal. This expansion due to corrosion is widely held to be the commonest cause of cracks in the crowns of bells.

Whenever old church bells, university bells, & tower bells are refurbished, it is normal practice to remove as much of the iron stumps (by drilling them out) as possible to avoid future trouble. Exceptions to this may be made in cases of the very oldest of bells. It can reasonably be argued that, if cracks have not formed from this cause after several centuries, the bell is probably not subject to the problem. Such exemption permits the preservation intact of the oldest examples of the bell-founders craft.

Tuning Church Bell, University Bell, & Tower Bell Clapper

Repeated blows of the clapper (or external hammer) at the same point on the soundbow (inside or outside) of a bell give rise to depressions forming in the bronze. If these advance to … … 10% or more of the unworn thickness, turning the bell or moving the hammer is necessary to reduce the risk of cracking. When a bell is rehung, the clapper and any hammer should strike upon an unworn thickness of the soundbow and preferably at 45° from any welded crack.

Church Bell, University Bell, & Tower Bell Chime Hammer

Hammers should be arranged to strike an unworn thickness of the soundbow. Where electric hammers are fitted, a clearly labelled override or isolator switch should be prominently positioned in the ringing chamber. A bright red light should signify that it is unsafe to swing the bells and a bright green one that it is safe to do so. Clock and tune-playing machine hammers should be fitted with pull-off wires and fastenings in the ringing chamber, together with a notice warning that they must be pulled clear while the bells are being swung. Extension ropes should be fitted only to bells without clock hammers. Tolling hammers operated from levels other than the ringing chamber should include a simple device to prevent the hammers operating when the bells are being swung. Hammers and ropes should be arranged to minimize the chance of a bell becoming damaged as a result of excessive impact, or of damping by holding the hammer against the bell immediately after impact.

Welding Cracked Church Bell, University Bell, & Tower Bells

Cracks may be repaired by welding. Given the peculiar composition of bell metal, this is a highly specialized task.

Church Bell, University Bell, & Tower Bell Removal of Canons

Canons are bronze loops once incorporated into the crown of a bell by which they could be fixed with iron straps to wooden headstocks. When steel replaced wood for the latter, bells were then cast with flat tops to be bolted directly to the headstock. When re-hanging old bells, it may be appropriate to remove the canons to create a flat top or to provide a steel canon-retaining headstock. Having said that, as a general principle, canons should not be removed. This general rule may be relaxed only if the bell is not identified as of historic significance and to be hung for full circle ringing. Particularly fine or unusual canons should be retained regardless of the bell’s age, and others should be retained where it would help balance bells in a ring which includes other bells with canons.

Church Bell, University Bell, & Tower Bell Tuning

A set of bells should sound musical, balanced, and in tune. Bells are fixed pitch musical instruments and do not go out of tune to any great extent. Where bells are not in tune, or where they are poor tonally, careful and limited adjustments to the notes and principal harmonic tones can usually be effected. In common with all other musical instruments, bells produce a complex sound made up of the nominal note and a series of harmonics. These are produced at different points in the bell’s profile and are closely linked to the various diameters. A ring of bells will normally yield a diatonic scale (in the Western world, sometimes called a ‘natural’ scale). However, prior to the late 19th century, the tone of an individual bell and the relative pitch of each one in a ring was largely the product of the founder’s artisanship.

Tuning involves the removal of metal from a bell; thus tuning, or further tuning, produces a small but irreversible change in both appearance and sound. In the case of bells worthy of preservation, there is a presumption against tuning. Tuning usually involves adjustments to all the bells within a set. Where the set consists of only three or fewer bells, tuning is rarely worthwhile.

Bell profiles which delivered accurate pitch were arrived at by an iterative process and some foundries were notably more successful than others in achieving satisfactory results. Digital measurement of the frequencies produced and an understanding of their optimum relationship now allows tuning by machining, usually of the inner surface, which can lower the pitch of the partials by up to a semitone. The process can be applied to bring the tuning of a ring of old bells into better alignment with one another and to improve their tone.

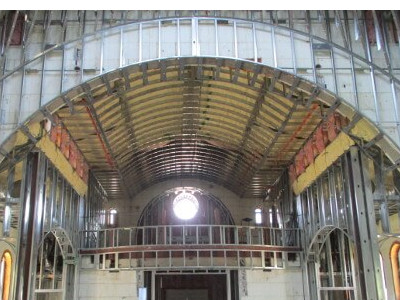

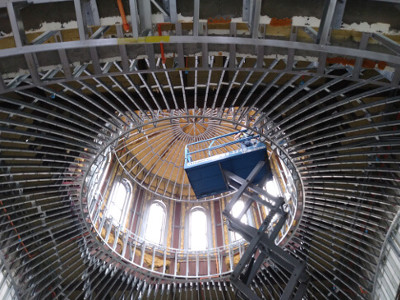

Church Bell, University Bell, & Tower Bell Frames

Bell frames are very much ‘out of sight, out of mind’ Old timber frames can create difficulties for change-ringers and, in severe cases, cause damage to tower masonry. If the joints between sections have loosened, then the frame will distort during full-circle ringing. This acts to dissipate some of the energy expended by the ringers, who must work harder as a consequence.

It is not unknown for the heavier bells in a ring to cause sudden ‘shifting’ of elements of the frame. Such movement is, typically, measured in only small fractions of an inch but may be sufficient to disturb the swinging of the lighter bells. Ringers strive to exert precise control in order to produce regular striking, but a ‘mobile’ frame can make this very difficult to achieve. In the most severe cases, and where the perimeter of a frame lies close to the tower walls, movement of a frame can effectively turn it into a ‘battering ram’ with consequent damage to masonry.

Bell hangers learned very quickly that large forces are exerted as bells swing through a full circle. A widely used rule-of-thumb gives that each bell exerts peak vertical and horizontal forces equivalent to four times (4x) and two times (2x) its weight respectively. The design of timber bell-frames of massive construction evolved and these had to be securely anchored into the tower walls. Steel has now almost completely replaced timber for new frames and achieves similar strength and stiffness with far more slender proportions, however the need for secure anchoring remains.

Modern developments in other technologies also allows bells to be struck by electro-magnetically operated hammers. These can be mounted on the frame alongside the bells or hung inside the bells to replace conventional clappers. Electronic control systems allow choices of ringing style at the push of a button

President and CEO

S F Glaser, Inc

Click to Call or (626) 841-1859

Click Here for Electronic Bells & Carillon Systems

Click to Call or (626) 841-1859

Clock Tower, Bell or Bell System Clients Include

- Christ Cathedral Catholic Church

- Mission San Juan Capistrano

- First Congregational Church of Redlands

- Annunciation Catholic Church

- Stanford University

- Holy Cross Catholic Church

- City of South San Francisco

- St. Anthony’s Catholic Church

- Avondale Church of God

- BIOLA University

- Twin Towers United Methodist Church

- St. Patrick Catholic Church

- St. Archangel Michael Serbian Orthodox Church

- USC

- Antioch Historical Museum

- St. Boniface Catholic Church

- Bolero Winery

- St. Columban Catholic Church

- St. Clément’s Anglican Church

- St. John’s Episcopal Church

- St. Mary’s Catholic Church

- St. Stephen’s Catholic Church

- St. Veronica Catholic Church

- Calvary Catholic Cemetery

- Christ Church

- Center of Praise

- Europa Village

- Queen of Apostles Catholic Church

- Holy Trinity Catholic Church

- City of Sacramento

- City of Garden Grove

- St. Mary’s Catholic Church

- Annunciation Greek Orthodox Church

- UCLA

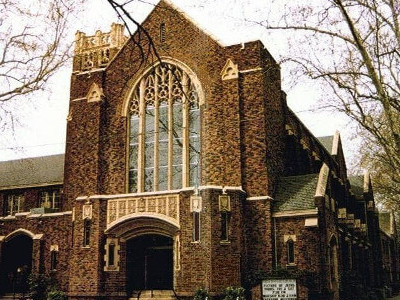

S F Glaser has been a trusted name in southern California since 1986. For over 36 years our company has provided a wide range of high quality, professional services to places of worship, schools, municipalities and businesses throughout California, Arizona and Nevada. We specialize in the design, installation and maintenance of digital carillon systems, cast bronze bells and bell automation systems as well as outdoor clocks and clock towers.

With over a thousand projects under our belt, the Glaser team has built a reputation based upon pride of workmanship, integrity and dependability. We work closely with our clients, listening carefully to every word spoken to make sure their needs are met with full satisfaction. Our goal is simple: to provide the best service money can buy. We do what we love and we love what we do. As president of this company, you have my word that you will always be given an honest opinion. Whether it is an existing system that can be repaired or a new one, you will be presented with the most affordable options available along with more advanced systems that may better serve your needs. We want you to feel comfortable before proceeding with any project.

We welcome the next challenge and look forward to working with you on your next project.

SF Glaser, Arcadia CA Serving Electrical Needs since 1986